Posted on October 31, 2021

For over 2,500 years, coins have served as a means for allowing people to trade goods and services. During that time, the process of producing these coins has changed through advancements in technology. From the original ancient Lydian and Ionian Greek processes to the hyper-efficient computerized methods used today, we’ll explore an overview of the history of technological advancements in the minting process.

In 2020, the U.S. Mint produced a staggering 14.8 billion coins. So far, in 2021, coin output continues to remain high, averaging over 1 billion coins minted per month. In July 2021 alone, over 1.5 billion cents, nickels, dimes, and quarters were struck. Though this figure represents an 11.3% decrease from July 2020, it marks an 11.3% increase from the previous month. (This change was driven primarily by a 20-plus percent increase in quarters and dimes.)

The billions of coins minted in the U.S. each month are orders of magnitude removed from some of the original minting innovations, which involved casting into molds, or nothing more than an anvil, a pair of dies, and a strong arm to hammer an impression into a blank metal coin. This technique enabled the producers to create roughly 100 new coins per hour (in contrast, the U.S. Mint has the capacity to produce millions of coins per hour).

Obviously, a lot has changed since the first production of coins. Originally, mints grappled with three main challenges:

Thanks to modern technologies like electricity, computer design, and automated high-speed presses, coin production today operates on a massive scale that minimizes manual labor.

Let’s take a look at the old-fashioned methods of producing coins…

Though the exact origins of the first coins are disputed, it’s generally accepted that the first modern production of coins appeared around the seventh and sixth centuries BCE in India, China, and Ancient Greek communities and their neighbors around the Aegean Sea.

During that time, coins were made by hand, though some tools did aid this operation. Perhaps the most notable technology at this time was the clay mold. Bearing the size and shape of a coin, the mold served as a receptacle for molten metal, which was poured into the mold and allowed to solidify, forming a coin.

A mold could contain a number of coin-shaped cutouts, allowing coin makers to produce multiple coins at once. Another early innovation in coin production was the punch-marked coin seen in ancient India. These irregularly-shaped coins were made by melting down metal, rolling the metal into sheets, cutting pieces of the metal to make coins, and then punching them by stamping symbols or images using handheld dies.

In the Kingdom of Lydia, in what is modern-day Turkey, artisans began the minting process with blank pieces of pre-weighed metal coins called planchets (we still call them “planchets” or sometimes “blanks” today). According to the well-known historian and writer Herodotus, the Lydians were the first to make gold and silver coins, so many consider this the earliest minting technology.

After heating the metal to soften it, the planchets were put atop an anvil and held in place with a pair of tongs. Next, an engraved die was positioned on top of the planchet, and a hammer was used to strike the die and stamp the design into the coin. As you’d imagine, these coins only had a design on a single side.

That changed soon…

New mints quickly began popping up in the Mediterranean region, leading to the next advancement in coin production. Soon, these producers began using two dies to imprint different designs on both of the coin’s faces from the same hammer strike. In addition, more manpower made the operation more efficient. Soon, it was discovered that coins could be produced far more expeditiously when each craftsman was assigned a specific task — one worker positioning the planchet, a second securing the die with tongs, and a third to man the hammer. (If you’re thinking that Henry Ford rediscovered the advantages of “assembly line” technology in the early 1900s, you’re correct.)

New mints quickly began popping up in the Mediterranean region, leading to the next advancement in coin production. Soon, these producers began using two dies to imprint different designs on both of the coin’s faces from the same hammer strike. In addition, more manpower made the operation more efficient. Soon, it was discovered that coins could be produced far more expeditiously when each craftsman was assigned a specific task — one worker positioning the planchet, a second securing the die with tongs, and a third to man the hammer. (If you’re thinking that Henry Ford rediscovered the advantages of “assembly line” technology in the early 1900s, you’re correct.)

For the ancient Greeks who valued aesthetics, using engraved dies allowed them to incorporate beautiful images onto both sides of each coin. Around the 5th century BCE, Greek coins had popularized the inclusion of iconography on coins, from gods and heroes to city symbols and even puns.

The ancient Romans, on the other hand, actually preferred to cast their coins in clay molds. Initially, this was achieved by pouring molten metal into clay molds and allowing them to harden. Ancient Roman coins were originally made of copper and were quite large, which meant hammering would require a tremendous physical effort. Casting allowed the Romans to easily standardize weight and shape and was much less labor-intensive for producing these bulky coins.

Recognizing the need for additional denominations, the Romans continued to utilize casting to mint coins of various sizes using different-sized molds; this made it easy for buyers and sellers to distinguish coins of differing values and offer a change in smaller transactions. The Romans also added engravings to the molds, which often included depictions of gods or exotic animals. Within a few centuries, however, the Romans gave way to the prevailing method of using a hand-held dies and a hammer to strike coins

And these were the last innovations in minting processes for centuries…

For well over a thousand years, minting technologies stagnated. Coin makers tinkered with purity levels and experimented with different amalgams (blends of different metals), but there were virtually no notable changes to the minting process itself.

During the late Middle Ages, producers of coins finally began to tinker with novel technological innovations. Rather than continue with the traditional method of individual planchets that were pre-weighed, coin makers started the process with a blank sheet of metal, hammering the design directly onto the sheet and cutting it out to complete the coin. This allowed multiple coins to be struck at the same time, vastly speeding up production.

Unfortunately, this method didn’t guarantee uniform sizing of the coins, which led to opportunistic individuals profiting by shaving off the metal edges, melting down the metal, and selling them for a profit — a practice known as coin clipping. Coin clipping had been a problem before, but now it was a widespread, rampant practice — so much so that it became an organized crime business. It wasn’t long before many of the coins circulating were worth more than their face value, posing a significant problem for the English Treasury. Merchants were forced to weigh coins rather than simply accepting them at face value, which slowed commercial transactions immensely.

Fortunately, one of history’s greatest geniuses came to the rescue.

In the late 17th century Sir Isaac Newton, the famed mathematician, and physicist devised a plan to combat coin clipping and forgeries. After being appointed Warden of the Royal Mint, Newton implemented new technologies to discourage coin clipping. These unique and improved coins minted under Newton’s watchful eye were perfectly round in shape and included milled or reeded edges.

In the late 17th century Sir Isaac Newton, the famed mathematician, and physicist devised a plan to combat coin clipping and forgeries. After being appointed Warden of the Royal Mint, Newton implemented new technologies to discourage coin clipping. These unique and improved coins minted under Newton’s watchful eye were perfectly round in shape and included milled or reeded edges.

While counterfeiting still occurred, creating a convincing counterfeit coin became much more difficult and time-consuming. In addition, Newton’s efforts had finally hampered the widespread practice of silver coin clipping in England. This deterrent worked so well that milled ridges were widely adopted and implemented through die collars, still used in mints today.

Around this same time, in Germany and Sweden, coin makers started using early versions of a trip hammer, similar to those sketched by Leonardo da Vinci. These innovators designed the trip hammer to harness the power of gravity to replace the human arm wielding a hammer to strike coins manually.

In Sweden, this technological advancement was modified and evolved into the tilt hammer press. Using a capstan driven by humans, horses or even a waterwheel, the tilt hammer press would raise a heavy hammer into the air through its pulleys, dropping it down with immense force onto metal sheets. The tilt hammer press sped up the minting process and allowed for a more significant force output from the hammer compared to strikes from a human hand. This opened the door to the creation of larger coins and multiple coins minted from a single strike of the hammer.

However, both hammer and tilt presses weren’t much more than enhancements of the methods used by the Ancient Greeks centuries before. True technological innovation was still ahead…

One of the most significant technologies in minting history was the screw press, first introduced in 16th-century Europe. The screw press represented an important innovation in coin production and was one of the only substantive technological developments since striking and casting methods.

The screw press was so important as a next step in minting technology because it addressed many of the common challenges treasuries faced.

Minting with the screw press focused on using two heavy iron screws to cut coins out of planchets. While the screw press was efficient for striking coins, it required a steady supply of planchets. The screw press reduced the human resources required to mint new coins, ensured perfectly round coins every time, and made coins even more difficult to counterfeit.

While the screw press was more efficient than casting and striking, it still required several men for operation. One individual served as the coin setter, inserting blanks and removing the completed coin after pressing. On either end of the screw press stood one or two men, whose job was to swing the balance arm back and forth; these workers were known as spinners.

Spinners were tasked with pulling on opposite ends of the balance arm, which in turn caused the spindle to be driven down onto the blank. The screw press employed the same general principles as striking by hand. A die was affixed to the end of the spindle, which struck the face of the blank; simultaneously, a stationary anvil die would press a different image onto the opposite side of the coin.

In the 1700s, a later development of the screw press included adding lead weights to the balance arm, which added more force to the press. The screw press continued to be a popular way to make coins into the late 18th century and was the method of production first used in the United States Mint upon its establishment in 1793. Despite its status as an innovative minting technology, the screw press was never challenged to supply currency for an entire country.

The U.S. Mint needed a technology that would yield millions of coins, not thousands. Luckily, the Industrial Revolution was right around the corner.

As the Industrial Revolution made waves through America and Europe, Joseph Bramah, a British engineer, was busy devising the hydraulic press. The hydraulic press uses the force of fluid in a container to create a magnified mechanical force. Hydraulic pressure is generated by the original movement, giving the hydraulic press its force.

In simpler terms, the hydraulic press works because when applying pressure to a fluid in a confined space, the pressure throughout the entire fluid is affected; this, in turn, can generate a mechanical force via pistons, which act as pumps to exert the force against the sample or plate. Bramah’s hydraulic coin press offered a way to consistently and efficiently stamp images into coins with the impressive force generated by fluid.

As much of an improvement as it was, the hydraulic press still relied on muscle- or water power to stamp designs onto coins. But that was about to change…

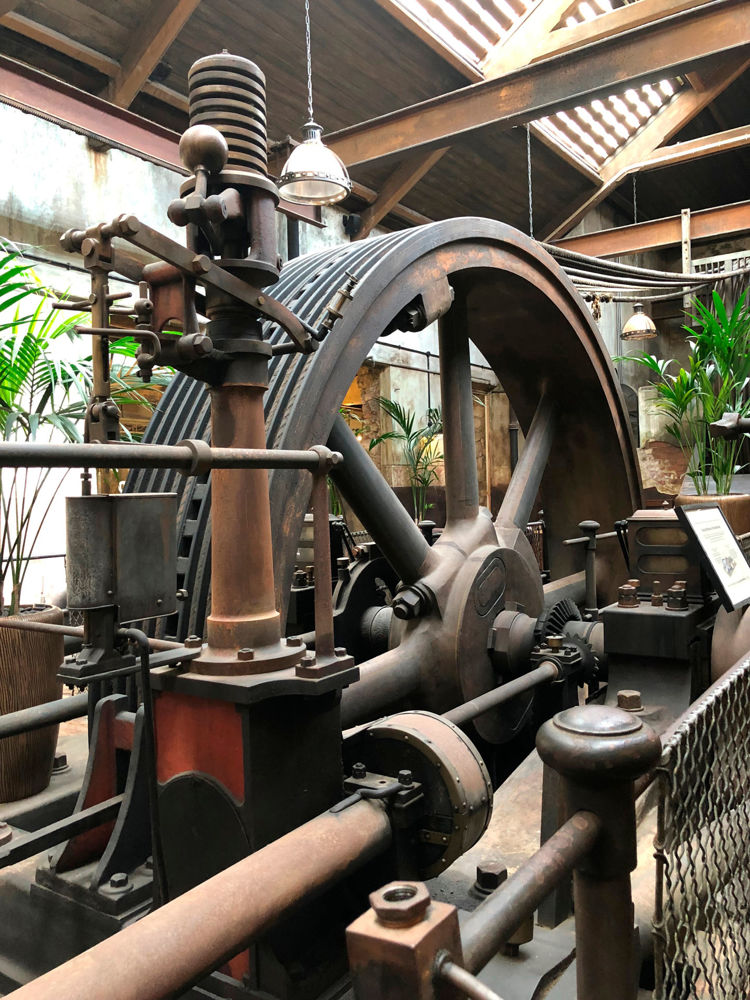

As the 18th century was winding down, coin innovators introduced the mighty power of steam as a way to ramp up coin production. Matthew Boulton, a manufacturer, founded the Soho Mint in 1788. Boulton believed that he could find a better way to mint coins, which would resolve the unmet need for small change. The Soho Mint was home to the world’s first steam-powered coin press.

As the 18th century was winding down, coin innovators introduced the mighty power of steam as a way to ramp up coin production. Matthew Boulton, a manufacturer, founded the Soho Mint in 1788. Boulton believed that he could find a better way to mint coins, which would resolve the unmet need for small change. The Soho Mint was home to the world’s first steam-powered coin press.

Instead of relying on power from humans or horses, the Soho Mint’s steam press was powered by steam pressure, which moved pistons to drive the screw press and produce as many as 84 coins per minute. In other words, the strength previously provided by humans (or horses, or waterwheels) was at long last replaced by a new and more efficient technology.

Boulton’s steam presses quickly gained recognition in England, and the Royal Mint soon contracted him to aid in the production of coins for the British government.

In the early 1800s, German mechanic Diedrich Uhlhorn paved the way for the minting industry to finally advance beyond the antiquated screw press. Uhlhorn’s knuckle-joint press (also known as a toggle-joint press) helped automate coin production through a flywheel and a hinged joint that acted similarly to the bending of a human knee. The knuckle-joint press ejected completed coins and immediately filled their place with another planchet fed by the flywheel. This removed yet another human element from the minting process and resulted in faster coin production.

Meanwhile, in France, workers were improving upon Uhlhorn’s knuckle-joint press with the emergence of the Thonnelier Press. In 1836, Thonnelier’s press was sent to the United States Mint in Philadelphia, where Franklin Peale, an employee of the Mint, made further improvements to it. Thonnelier’s press, which ran on steam, was the first powered coin press used at the United States Mint.

The 3D pantograph was another 19th-century minting technology that contributed to faster, more efficient coin-making. The pantograph was a revolutionary idea because it used a relatively simple process to give sculptors and artists the freedom to duplicate an object or drawing, and in the process to render it larger or smaller. The arm of the pantograph is adjustable and makes a larger or smaller-scale copy of whatever is being drawn or traced. The first pantographs worked in two dimensions, which just isn’t sufficient for the three-dimensional reality of minting coins.

3D pantographs were significant to minting because they addressed the need for a better way to make coin dies, not just coins themselves. Remember, dies are the part of the press that imprints images and text on the finished coin. So enhancements in die production allow greater detail in coinage designs.

By far, the most well-known of these 3D pantographs was the Janvier Reducing Machine, empowering artists to scale their larger designs and engravings onto coin seamlessly dies of smaller, varying sizes. For obvious reasons, the Janvier Reducing Machine became a staple in mints around the world. These technologies were so significant that the U.S. Mint continued to use them until as recently as 2008, while they are still operating at other mints.

To ensure gold and silver coins were fit for circulation, the Royal Mint had to find a way to measure the weight of these coins. A crucial technological tool of the mid-19th century was the automatic balance. Employing people to weigh individual coins was a terribly inefficient process and one that was solved with the automatic balance machine.

These balances included a steam-powered shaft that moved coins from a feeder stack onto a scale pan. This quality-control step ensured the mint produced coins of consistent weights (which was of crucial importance when all coins were valued based on their precious metal content).

The automatic balance proved itself instrumental in accelerating and automating part of the minting operation.

Today, modern minting relies on two major technologies — electricity and computers. Every aspect of the minting process uses electricity, which offers a significant advantage over the previous power sources like steam or manual power generated by humans or animals.

Computer-generated digital images have simplified designing and reduction for coin dies, which have replaced the reducing machine. Utilizing computer programs, traditional sculpting, or a combination of the two methods, artists can design dies that are digitally editable and reproducible. Instead of the reducing machine, computer programs today implement digital scanning to reduce designs for coins to an appropriate size.

From there, a computerized numerical control (CNC) milling machine will automatically cut the design onto a steel end, called the “master hub.” The master hub is then taken to a hydraulic press where it’s sandwiched against another piece of steel, creating a negative image of the original design and giving us our master die. The master dies continue their journey by going through the same press as the master hub to create a negative image, providing working hubs from which actual coins are pressed.

The next step in the modern minting process involved coils of metal, which are fed into a machine known as a blanking press to cut out blank coins. A coil is a sheet of metal that is rolled up to make it easier to transport. Coils allow mints to work very efficiently and ensure uniform sizing without having to manually feed sheets of metal into the blanking press.

Blanks have to undergo some additional priming before they’re ready to be pressed. You’ve probably noticed the raised edges on a quarter, for instance; an upsetting mill achieves this. The blanks have now evolved into planchets that are ready for pressing. These planchets then travel on a conveyor belt down to the coining press, where they are automatically put through the coining press and stamped between the two dies.

When the coins are finished, they are checked for quality. Then, they’re sent by conveyor belt into counters, which automatically count the freshly minted coins and dump them into enormous tote bags in preparation for shipping and distribution.

The evolution of minting technology over the last 2,500+ years might seem like a linear progression, but there were undoubtedly technologies that were short-lived or outright rejected. For example, when coin makers thought of heating blanks to reduce the amount of force needed to stamp a design, they quickly discovered why the practice caused more harm than good. The heated coins would seldom come out an even disk, often resulting in sharp, ragged edges.

Another rejection of minting technology was roller die coinage, which appeared primarily in the 16th and 17th centuries. The idea behind the roller press was to speed up the minting process by rolling a curved, oval-shaped die over a strip of metal and then cutting the coin shape out after. Unfortunately, this method proved ineffective due to quality problems and the manually-intensive process of accurately cutting the images out of the metal.

Humans have been making coins for thousands of years. While technology has undoubtedly transformed minting, the core elements of pressing a coin are still surprisingly similar to the ancient practices of striking by hand.

Up until relatively recently, coin making hadn’t advanced very much at all. However, with the introduction of steam and electricity, automation became a reality for mints. Even in the most advanced facilities, dies resembling those from the 7th century BCE continue to play a foundational role in the production process.

The recent additions of digitization and computer automation have truly revolutionized minting technology and will likely continue to help advance and expedite modern minting.